The ZIEGLER FT-2000 adhesion tester / peel strength tester is tailored to the requirements of manufacturers, processors and users of adhesive composite materials. Its specifications correspond to the FINAT* and Afera** test standards. The sample table is driven using an electronically controlled encoder position control, which precisely maintains the speed.

The determined average tensile force is shown on the display of the measuring device. Pulling speeds of 10/20/50/100/150 mm/min or 1/2/5/7.6/10 m/min can be set. The standard pulling speed is 300 mm/min. Optionally, a motor-operated 90° pull-off is possible.

Working Principle

The Peel Force Tester is a horizontal tensile tester to perform bond strength testing. The sample table is equipped as a movable clamp with constant feed, while the fixed clamp is rigidly coupled to the load cell.

This can be used to measure properties such as release force and peel strength, e.g. at peel angles of 180° or 90° (option).

Testable Materials

- Friction films

- Adhesive films/foils/tapes

- Adhesive tapes with release material

- Adhesives

- Labels

- Self-adhesive films/foils/tapes

- Security stickers

- Seal Material

- Packaging tapes made of paper, plastic, textile and metal as well as materials with related properties.

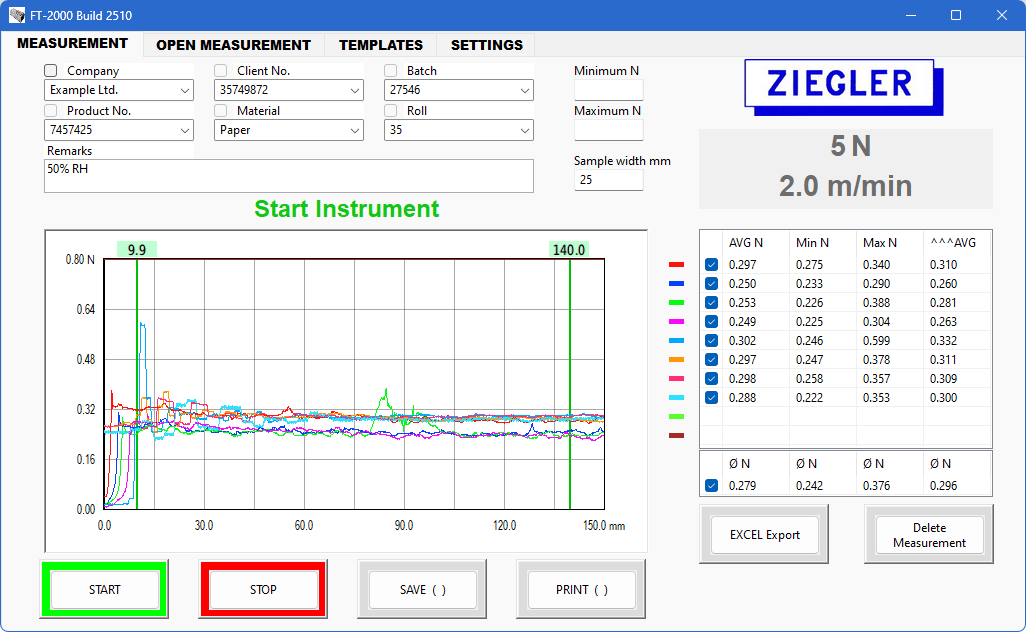

FT-2000 Data acquisition software

The FT-2000 data acquisition software (included in scope of delivery) is used for the data acquisition, evaluation, logging and data storage. Measurements can thus be automated safely and conveniently. The clear and intuitively designed user interface reduces training to a minimum of time.

- Compatible with Microsoft® Windows® 11

- Fast data transfer

- Unlimited number of measurements that can be taken

- Viewing up to 10 measurements at the same time

- Clear measurement log with graphic representation

- Maximum convenience when processing your data

- Reproducible readings

- Clearly designed user interface

- Intuitive with tooltips

- Reduces training to a minimum of time

- Service and support

Technical Data

|

| Force measurement: |

2x highly sensitive strain gauge load cells, 5 N and 50 N each |

| Drive: |

The sample table is driven by a high-quality servo motor with encoder position control, which precisely maintains the speed.

The standard pull speed is 300 mm/min; 10/20/50/100/150/300 mm/min or 1/2/5/7.6/10 m/min are selectable via the front touchscreen. |

| Travel: |

Standard Travel: 150 mm

Selectable travel lengths: 50, 100, 150, 200, 250, 300, and 360 mm. |

| Force display: |

The measured average tensile force is displayed on the measuring device's screen.

Measurement range: Load cell 5 N: Resolution: 0.001 N

Measurement range: Load cell 50 N: Resolution: 0.01 N |

| Accuracy: |

Force measurement: < 1% of displayed value +/- 2 Digits

Speed: < 2% of the selected speed |

| Operating voltage: |

100–240V/ 50–60 Hz/ 90 VA |

| Dimensions: |

L 670 x W 290 x H 200 mm |

| Weight: |

ca. 10.5 kg |

| PC-Connection: |

USB |

| Data Acquisition: |

FT-2000 data acquisition software (included)

|

| Included equipment: |

- 2-channel version with 5 N and 50 N load cell

- Sample plate float glass, 200 x 100 x 2 mm

- Sample plate stainless steel VA, 200 x 100 x 2 mm

- FT-2000 data acquisition software

|

* FINAT, Féderation internationale des fabricants et transformateurs d'adhésifs et thermocollants sur papiers et autres supports.

** Afera, the European Association for the Self Adhesive Tape Industry